Title: System Integration at ASML: linking technical content, test configurations, timing… and people!

Presentation accessible here: System_Integration_at_ASML

Abstract: ASML is one of the world’s leading manufacturers of chip-making equipment and has a lot of experience on System Integration, i.e. how to get from tens of thousands of hardware/software components to a fully integrated system that performs at the required nanometer-level specifications. The best practices from recent product integrations are combined and refined into a common way of working for System Integration that provides clarity and visibility to everyone involved. This way of working describes the definition and execution of the system integration strategy via so-called PERTs and configuration baselines, which have a strong link to the product breakdown structure and performance budgets of Systems Engineering. Furthermore, it defines a framework for consistent progress tracking of all integration steps that need to be performed by the delivering projects. Finally, it provides a structured way for making integration and test plans such that the timing of the integration steps and the required project deliveries is always clear. This way of working is key in managing the integration phase “where the going gets really tough” and where the projects need to deliver their hardware, software, and issue solutions to the test systems in the right order, at the right time, and with the right quality.

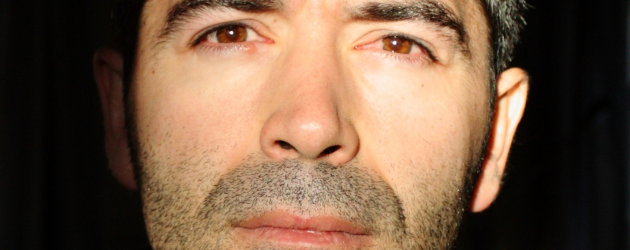

Biography: Niels Braspenning received the MSc. and Ph.D. degree at the Systems Engineering group, part of the Mechanical Engineering Department of Eindhoven University of Technology (TU/e), the Netherlands. Since 2008, he has been working in the System Integration department at chip-making equipment manufacturer ASML in Veldhoven, the Netherlands. In the role of System Test Engineer, he has experienced the various aspects of system integration & testing, involving (sub)system integration strategy and preparation, configuration management, system reliability, issue management, and execution planning & support. Since 2010, in the role of System Test Architect, he has been focussing on high-level, full-product integration strategies, integration-driven progress tracking towards program management, and on establishing a common Way of Working for the System Integration process to be used in all programs at ASML.